Air/Oil Separator design, build and test

Project Overview

This project involved designing and manufacturing a cyclonic air/oil separator prototype in collaboration with the Rolls-Royce University Technology Centre. The system was developed to separate entrained air from water in two-phase flow, replicating conditions found in aeroengine systems.

Design Challenge

The primary challenge was to create a compact, efficient separation system that could handle high flow rates while maintaining portability and visibility for testing. The device needed to fit within a 200×200×500mm envelope, weigh less than 20kg, and achieve less than 1% aeration in the output.

System Design

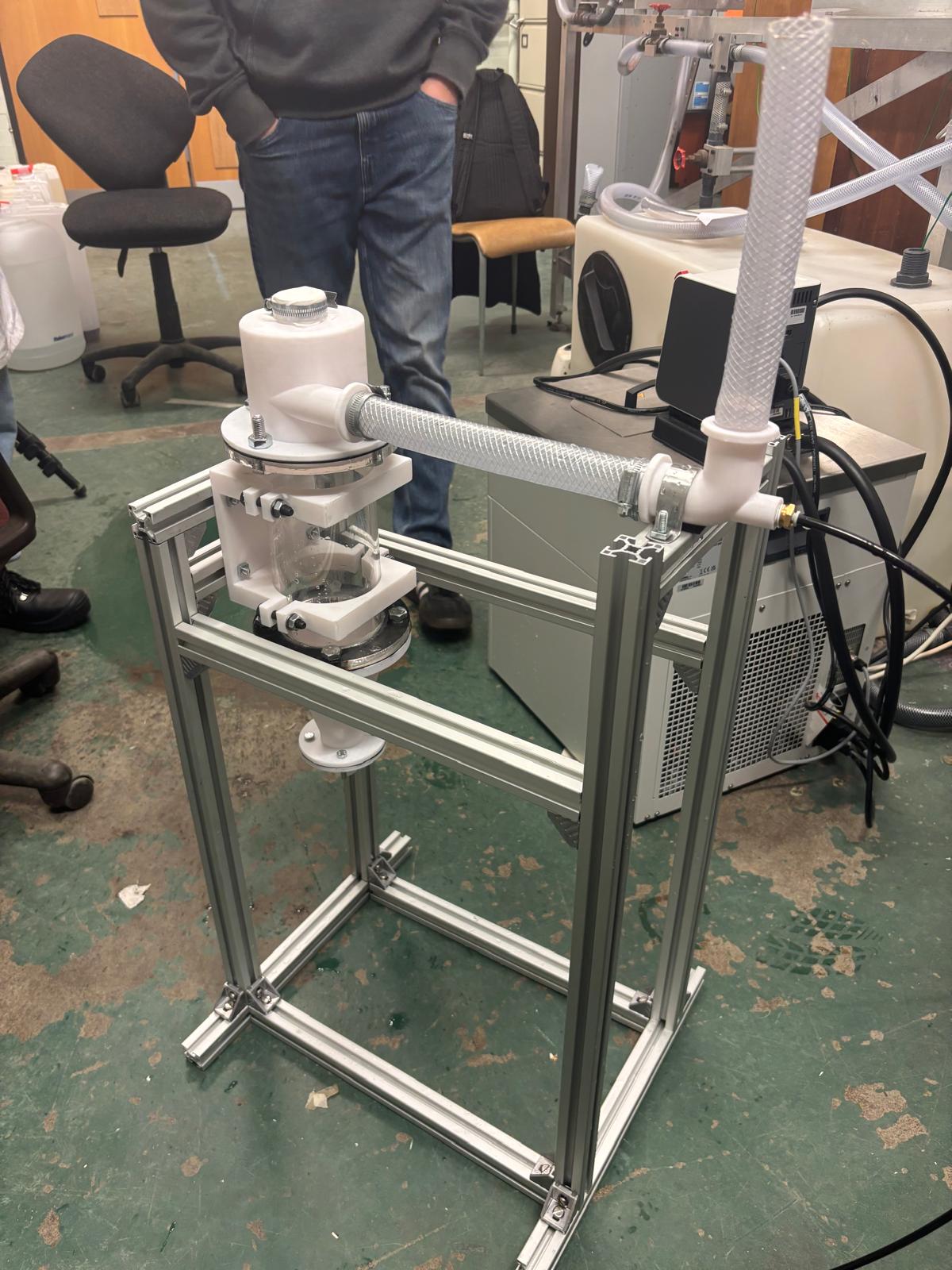

The prototype consists of three main subsystems:

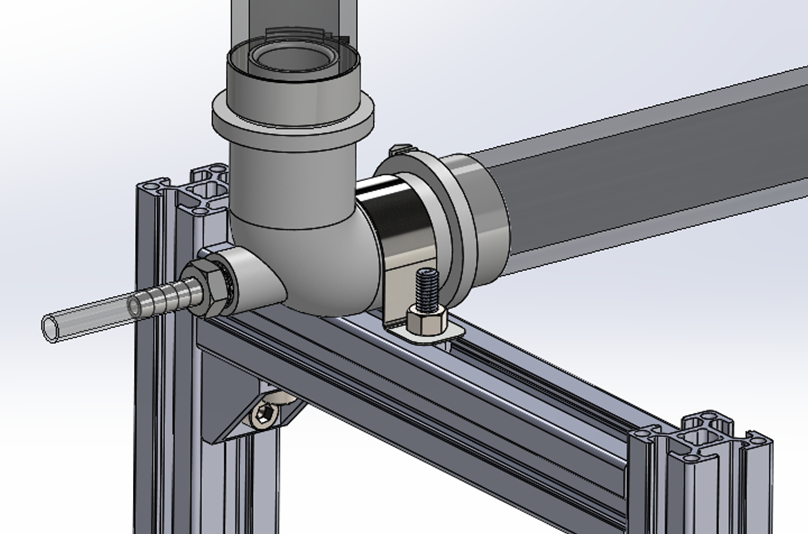

Aerator Subsystem

A custom 3D-printed L-tube design that injects compressed air into the water flow at 36 L/min, creating a stratified/wavy two-phase flow with dispersed air bubbles. The aerator uses a venturi effect to efficiently mix the phases while maintaining the required flow characteristics.

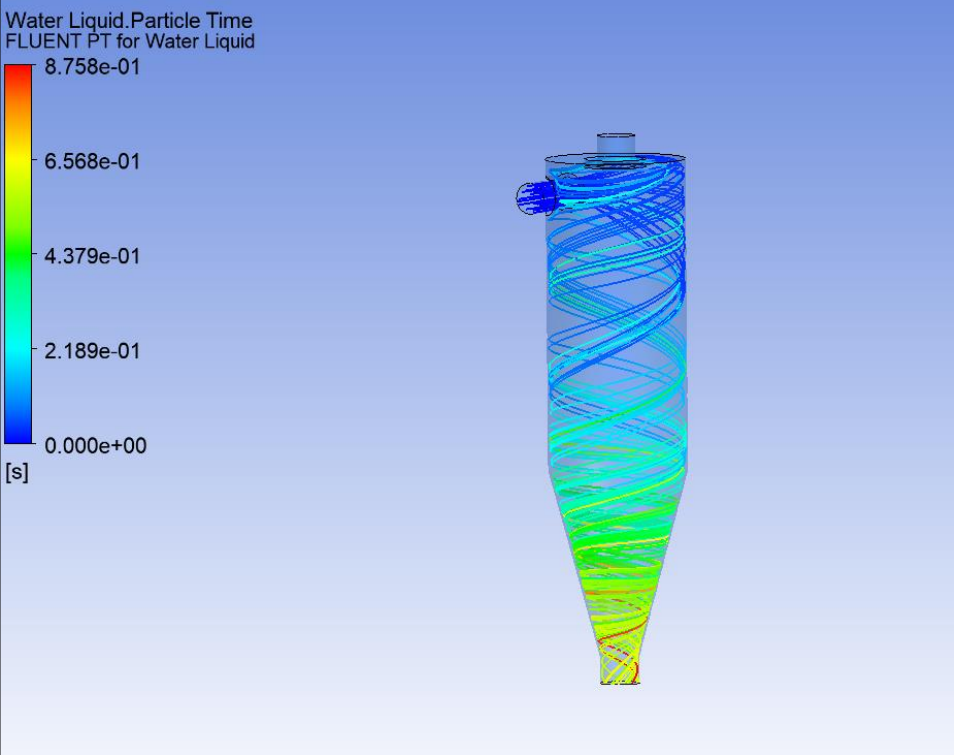

Cyclone De-Aerator

The core separation component featuring a transparent Perspex cylinder (90mm diameter, 360mm height) that generates centrifugal forces of 353N. The design includes a venturi inlet to accelerate fluid to 3.98 m/s, creating approximately 4 rotations during the 0.27-second residence time. A vortex breaker at the outlet prevents re-entrainment of air bubbles.

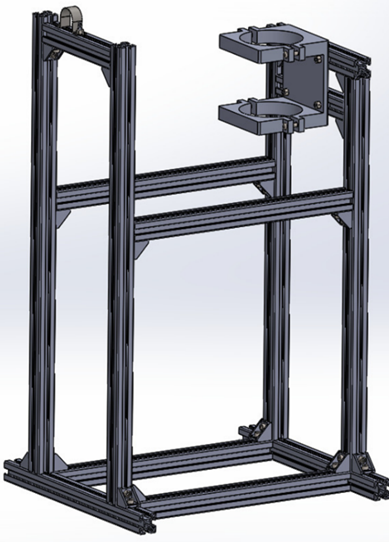

Support Framework

An aluminium extrusion frame (30×30mm profiles) designed for stability, easy assembly, and full visibility of the separation process. The modular design allows for simple disassembly and component replacement, with all joints using standard T-nuts and bolts.

Technical Approach

Technical Approach

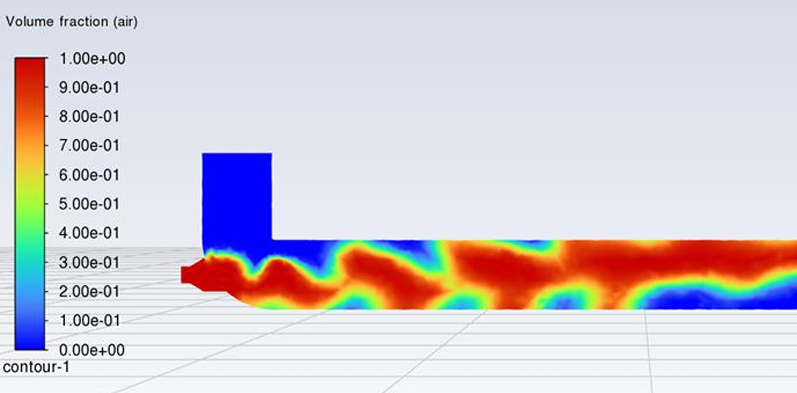

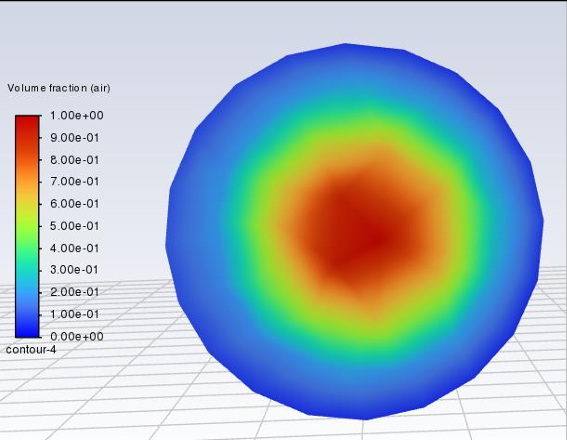

CFD Analysis

Extensive ANSYS Fluent simulations validated the design, confirming stratified flow development in the aerator and successful phase separation in the cyclone. The Volume of Fluid (VOF) method demonstrated clear interface separation between phases and verified the formation of the air vortex core.

Manufacturing Methods

Manufacturing Methods

- 3D Printing: Hydrophobic PLA used for inlet tube, funnel, vortex breaker, and outlet (total 63.6 hours print time)

- Perspex Machining: Laser-cut acrylic flanges bonded to cylinder using rapid-set epoxy resin

- Aluminium Extrusions: Cut to precise lengths for framework assembly

- Sealing: Neoprene rubber gaskets with calculated bolt pre-tension (59.16 Nm for M10, 15.76 Nm for M6)

Key Calculations & Analysis

- Two-phase flow regime calculations confirming stratified/wavy flow (Re = 10,362)

- Centrifugal force analysis proving 353N force generation at 88.6 rad/s

- Bubble migration calculations using modified Stokes' Law

- Re-entrainment velocity limits (4.25 m/s vs. actual 3.97 m/s)

- Beam bending FEA showing maximum deflection of 2.33 μm

- Gasket compression calculations ensuring leak-proof seals

Results & Testing

The design successfully met 10 out of 13 requirements at the Critical Design Review stage, with the remaining 3 requiring physical testing for validation. The prototype demonstrated compliance with all dimensional, weight, and safety requirements, with a final project cost of £380.18 (under the £450 budget).

Skills Developed

Skills Developed

- CFD simulation and multiphase flow analysis

- 3D CAD design and optimization (SolidWorks)

- Manufacturing process planning and scheduling

- Risk assessment and safety documentation

- Collaborative design with industry partners

- Project management and budget control

Reflection

This project provided invaluable experience in designing for real-world industrial applications. The collaboration with Rolls-Royce UTC added complexity and accountability, requiring adherence to professional engineering standards throughout the design process. The iterative design approach, supported by extensive calculations and CFD validation, ensured the final prototype would meet performance requirements while remaining manufacturable within budget and time constraints.

Key learning points included the importance of worst-case scenario analysis (film thickness calculations), the balance between design complexity and manufacturability, and the critical role of early stakeholder engagement in defining requirements. Future improvements would include implementing real-time pressure monitoring and exploring different cyclone geometries for enhanced separation efficiency.